Capabilities

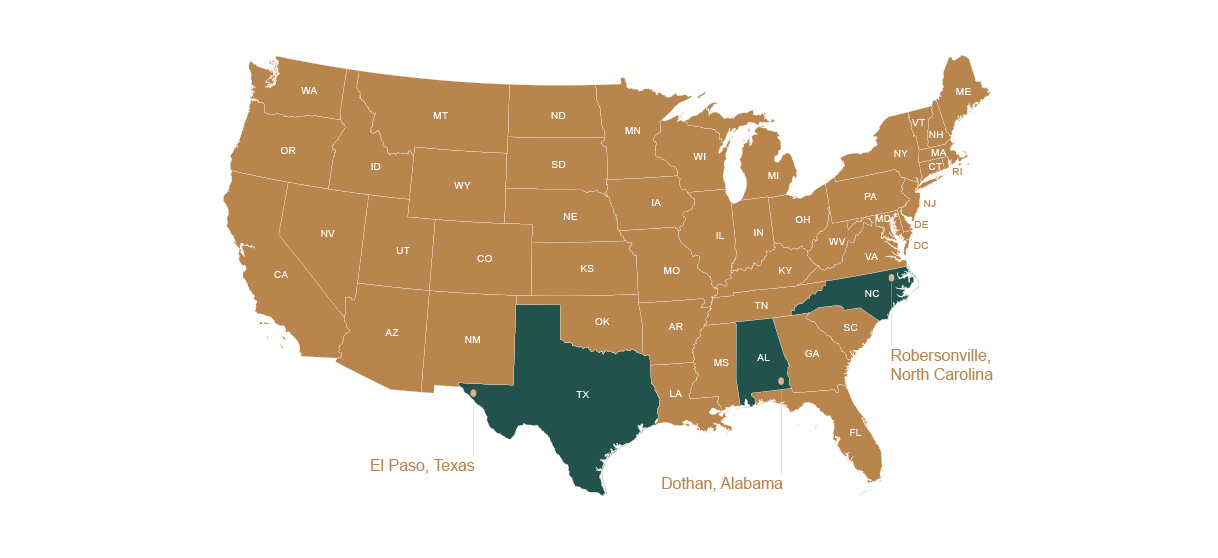

Our three primary facilities are equipped with state-of-the-art blanching, roasting, precision blending and packaging equipment. We continually research the latest equipment and technologies that translate to better quality, cost and food safety. As we look to form lasting and mutually beneficial partnerships with our customers, we will also make capital investments to support our combined objectives.

Current capabilities include, but are not limited to the following:

Processing & Roasting

· Oil roasting, including North America’s largest oil roaster

· Organic oil roasting

· Dry (oven) roasting

· Brining

· Honey roasting

· Kettle roasting and glazing

· Peanut blanching

· Seasoning application and custom formulations

· Precision blending and custom snack and trail mixes

Packaging

· Stand-up resealable pouches in multiple sizes

· Lay-down and peggable pouches in multiple sizes

· Single-serve tubes

· Multi-packs in multiple configurations to meet consumer, customer and channel-specific needs

· Plastic jars in multiple shapes and sizes

· Canisters in all industry-standard sizes

· Plastic tubs, designed for produce departments and similar applications

· Bulk cases for retail, food service and ingredient applications

· Supersacks for food service and ingredient applications

NEW! Sustainable Packaging Options

• Recyclable film – available for all flexible pouch options noted above

• New 2-piece plastic tubs made with post-consumer recycled plastic